*Courtesy of A. Davidhazy.

Latest News

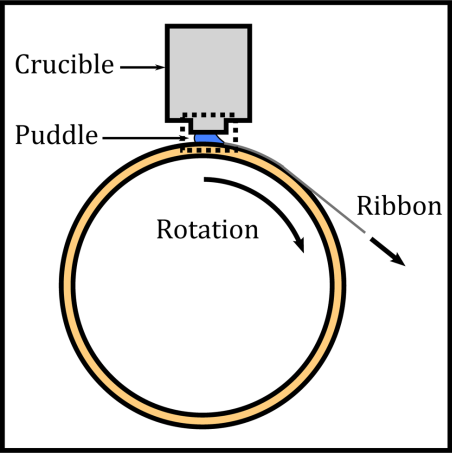

Planar flow melt spinning (PFMS), known alternatively as ‘planar flow spin casting’ or ‘single roll spin casting’, is a process to rapidly solidify molten metal in a single step. Liquid metal is forced through a nozzle onto a rotating substrate wheel where sufficient heat is removed to solidify the material into a thin ribbon (100 micrometer) at high speed (10 meter per second), ribbon which is subsequently spun off the wheel to be collected. PFMS has diverse application, for example, to the fabrication of amorphous magnetic ribbon or of nano-crystalline structural steel foil. Our goal is to put this and related processes on a firm scientific foundation to enable innovation in product material properties and advanced manufacturing technique.